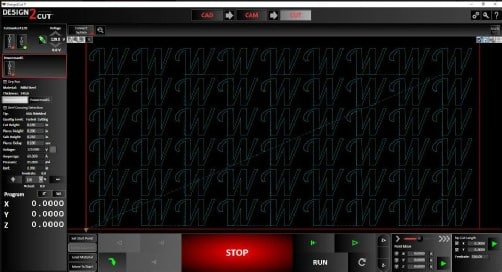

When it comes to Software for CNC Plasma Cutting, you can break things up into 3 distinct categories: CAD or ART, CAM, and CNC machine control.

CAD (Computer-Aided Design) or ART Software

This is where you will be designing the part, or artwork, that you will be cutting. This can include making a complex bracket or support to taking an image of your favorite car, and turning it into something that you can cut. Very few programs do both CAD and ART perfect. Most are suited to one or the other. Itls not uncommon to use multiple programs in this category when doing CNC plasma cutting.

CAM (Computer-Aided Manufacturing)

After you’ve created a part or object you want to cut, you export that in a file format that ends in .dxf (unless you use Design2Cut, an all-in-one software). This is the most popular CAD file format for machines to use. Once you have a .dxf file, you import it into your CAM Program. This is where you will set up the tool path requirements so the machine will know what it’s going to do and how to do it. To break this down in simple terms, this is where you will tell your machine what material you’re going to be cutting, how thick it is, where you want it to cut, start, and stop. All of the speeds, cut height, pierce height, and plasma cutting machine options come into play here.

Your software will allow you to build “tools”. Each tool can be a different material and thickness. You can get the values for these from your plasma cutter manufacturer. I often put Hypertherm Powermax65 or Hypertherm Powermax 85 on my Titan Series plasma tables. Hypertherm is the best when it comes to cut charts and data. They make setting up your tools and cut information very easy. No guessing or trial and error, like other manufacturers.

When plasma cutting, your CNC plasma table will need to know if it’s cutting on the inside of your lines, on your lines, or outside of your lines. If you have a bolt hole, you want it to cut inside the line so the hole is cut out. If you’re making a part, you will want it to cut on the outside of the finished part line.

This is also the program that creates your “lead ins”. A lead-in is a small line that connects to the line you want to cut. When your plasma cutter does its initial pierce to start cutting, it will make a hole which will be larger than the subsequent cut line. This hole is not desirable to have in your finished part, so we create lean-ins so that the hole is not part of the finished part. This will all become more clear as we move through this process.

CNC Machine Control Software

After your part is designed and exported as a .dxf file, you import it into the CAM program and create your tool path. Once this is done you export this as G-Code. G-code is the machine language that takes all of the information you have created and turns it into something that the machine can understand and work with.

In Plasma Cutting, you will have X motion, which is usually left to right. Y motion, which is usually front to back. And Z motion, which is the height of your torch up and down. The steppers or servos that are driving your machine need to know where to go and when and how fast. The plasma torch also needs to know when to fire, cut, pierce, and how long to stay on and how many amps to use.

There are a ton of things taking place nearly instantaneously, and the G-code is the direction to make that happen. G-code has to be matched to your machine and equipment. You cannot take g-code from someone else’s machine and use it on yours, unless they are exact copies.