Machine Control software builds on the CAD program and CAM programs and takes the G-Code generated by the CAM program and makes the magic happen. The Machine Control Software uses the G-Code generated in the CAM program to tell your motors when to move and how much, how fast to move and tells the torch when to fire and for how long and at what amperage. There are many more things happening here but that is a basic rundown of what the Machine Control program does. One of the most popular Machine Control software programs in the world is Mach3 its has been around for many years and controls all kinds of machines not just plasma. For more info on G-Code, check out our G Code Article. Below is an example of what G-Code looks like.

This G-Code to the left can be deciphered pretty easily once you know some basic info and terms about G-Code.

What do we recommend / Use

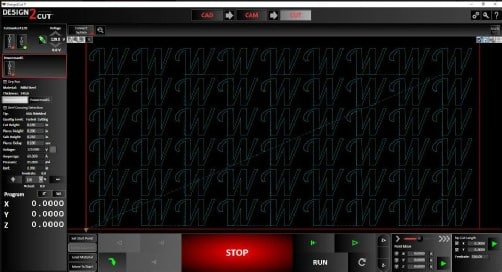

For our plasma tables at Westcott Plasma, we are using Design2Cut for our machine control program. While this program is proprietary to Westcott Plasma it can be adapted and used with other brands of machines and can be retrofitted to machines using other software options. What is unique with Design2Cut is that it is an all in one solution for your software. Meaning that it can take the place of three programs and allow you to build a CAD part, Complete CAM processing and send it to the Machine for cutting all in one program. This greatly simplifies the task of making something.

In most machines people use a CAD program like Corel or Drawplus to create the part or artwork they want to make. They then save the file as a .dxf file format. Then they open a program like Sheetcam and import their drawing. They process the part in the CAM software, then run a post processor to turn it into G-Code. Then they opened a program like Mach3 and imported the G-Code file from Sheetcam. Then they run the cut on the machine. You can see this process is time consuming.. and if you run into a problem with a cut, you have 3 places you need to check to find the problem and correct it.

With Design2Cut all of this happens in one place and one program. You can still use other CAD design programs and import the drawings into Design2Cut. Some people may be used to or comfortable with other design software so your not limited in that regard with Design2Cut.

To get a free demo of Design2Cut, check out our resources page.