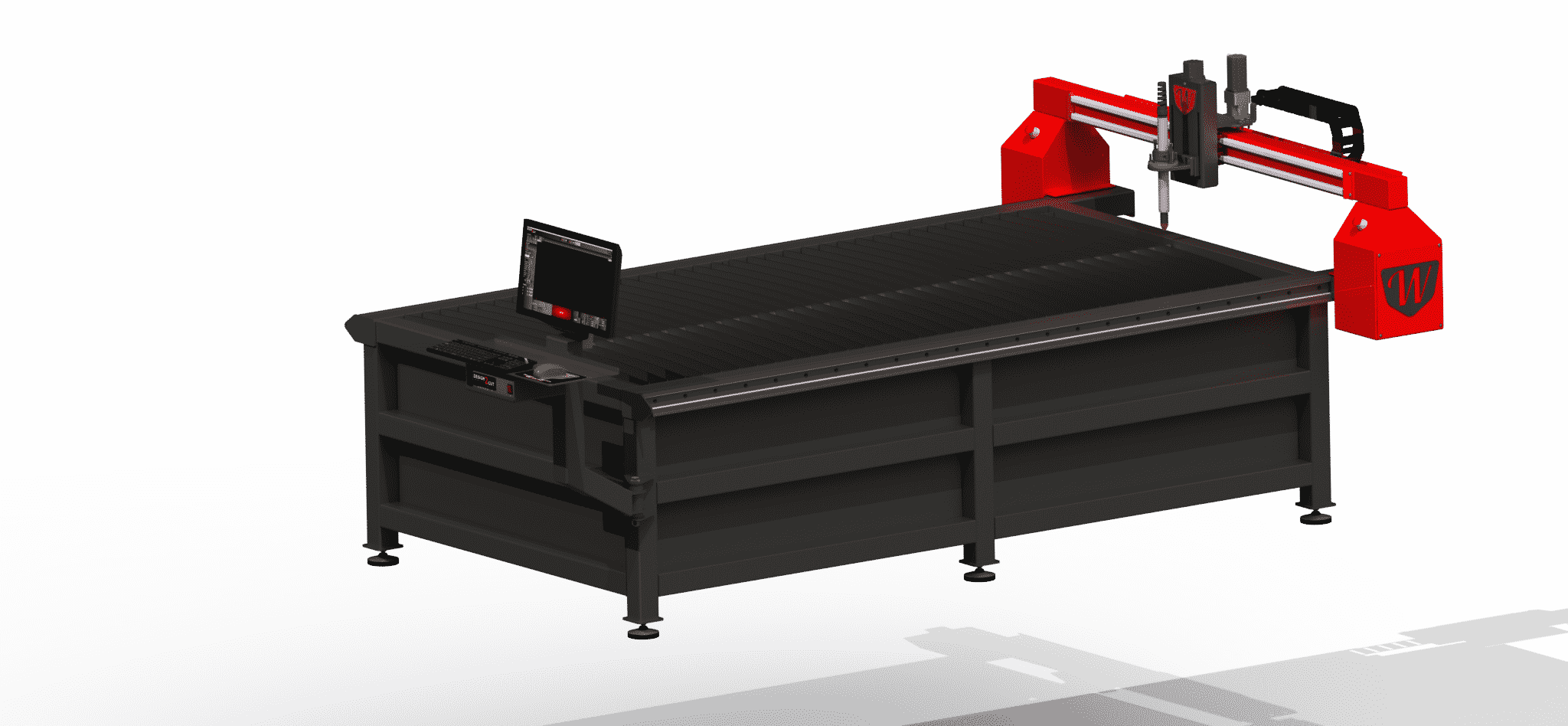

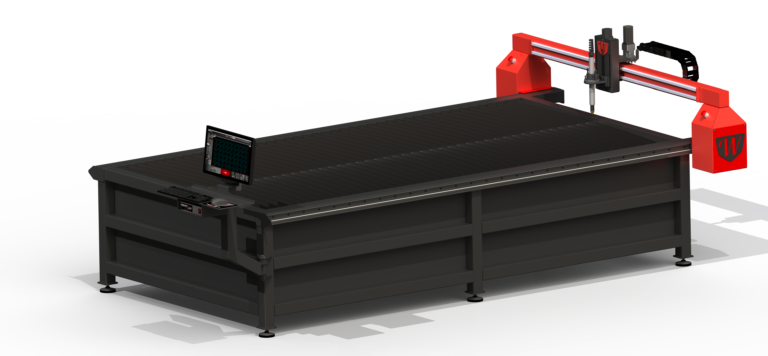

Our Titan Series X™ Tables were developed for shops with smaller budgets while maintaining the quality that they usually find themselves priced out of.

- Compact Size

- Perfect for Hobbyists & Small Businesses

- Affordable

Features and Overview

Our Titan Series X™ CNC plasma table was developed for shops with smaller budgets while maintaining the quality that they usually find themselves priced out of.

We took what we’ve learned while building and designing our Pro Series™ CNC plasma table and scaled it down into a lighter package that is best suited to a smaller shop, classroom environment or even a home garage while still giving the end user the abilities they need to cut parts fast and accurately time and time again.

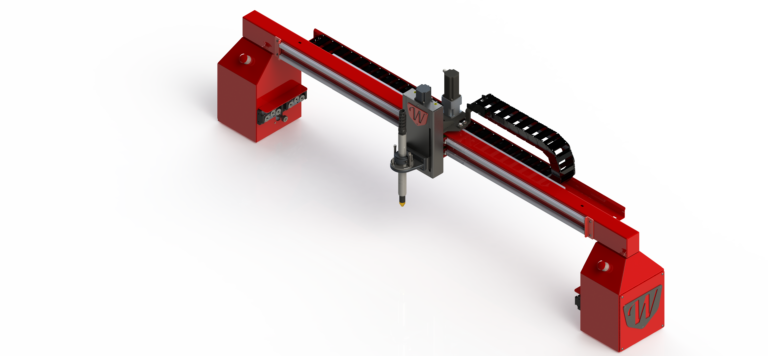

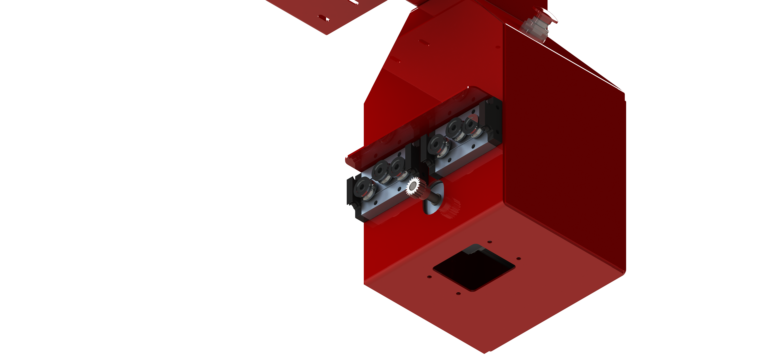

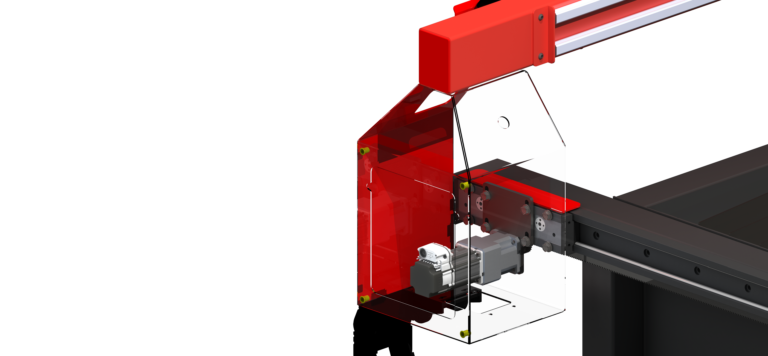

The Titan Series X™ is the only CNC plasma table in it’s class to offer features usually reserved for heavy industrial plasma cutting tables; dual collision sensors built into a billet aluminum torch holder mounted on dual linear rails with recirculating bearings. 454 oz NEMA 23 stepper motors with planetary gears drive the gantry which rides on precision linear guide rails with 6 precision points of contact at each end to keep the gantry level, straight and minimize any deflection, allowing the machine to achieve rapid movement speeds flawlessly.

Quick Glance

Familiar Windows Environment

Single Software Interface that allows CAD-CAM-CUT within one program.

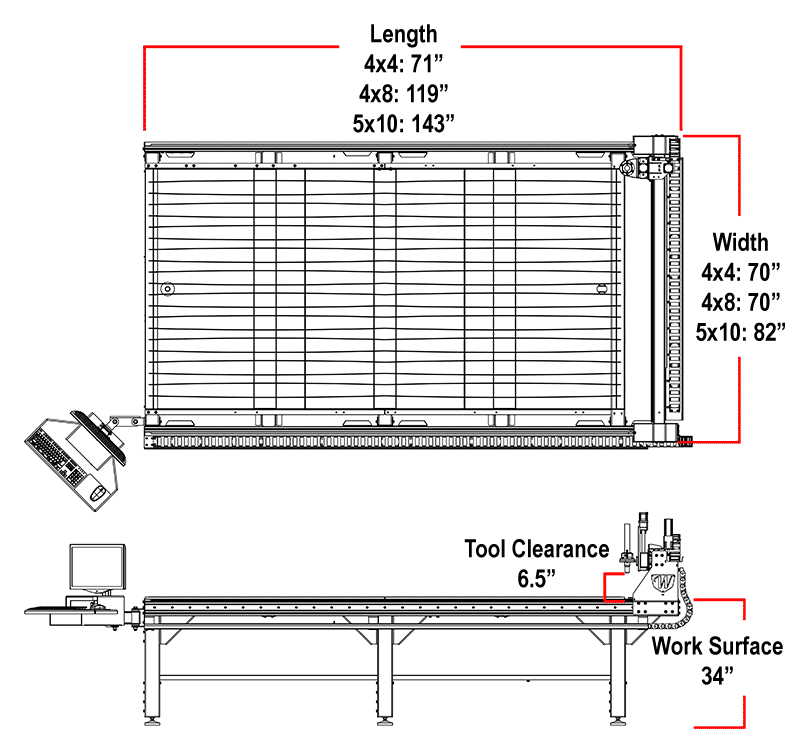

4'x4' , 4'x8', 5'x10' Size Configurations

Standard 1ph Power

Powder-coated Finishes

3" Deep Integrated Water Pan

Designed for up to 1" Plate

DESIGN2CUT™ SOFTWARE CONTROL FEATURES

CAD to CAM to CUT within one simple to use and intuitive software environment with integrated CAD/CAM you no longer need to worry about transferring and importing files from other software piece of software to another, all your settings for the entire process are stored within one piece of software which optimizes work-flow, and allows for quick on the fly changes.

The software was purposely built for CNC plasma cutting, with a focus on ease of use for anyone while still maintaining the ability to dial in specific process specifications.

- Custom Shape Library allowing you to quickly generate common shapes with simple value input.

- CAD/CAM/CUT™ allows you to easily draw or import your parts in CAD, you create efficient tool paths in CAM, and you cut parts accurately in CUT.

- Automatic Tool Path Generation makes for simple manipulation of feeds and speeds.

- Automatic Kerf Compensation gives the ability to change kerf of a profile, and allows you to change from a cutout to a part.

- Kerf Crossing Detection when crossing over an existing cut THC automatically adjusts to prevent torch diving.

- Basic Lead-ins allows you to change the location and type of lead in and lead out.

- Change the cutting order gives you the ability to optimize the cutting order of your nested parts.

- Grid Nesting allows you to create row and column nests.

- True Shape Nesting quickly and efficiently nests parts, minimizing material waste.

- Fix Drawing Tool automatically scans, identifies, and repairs errors in imported CAD files.

- Cut Charts are preloaded cut parameters for Hypertherm and Thermal Dynamics plasma cutters.

- Multipart and Multisheet nesting paired with True Shape Nesting.

- Simple Pause Cut, and Restart Capabilities, No need to interact with G-Code.

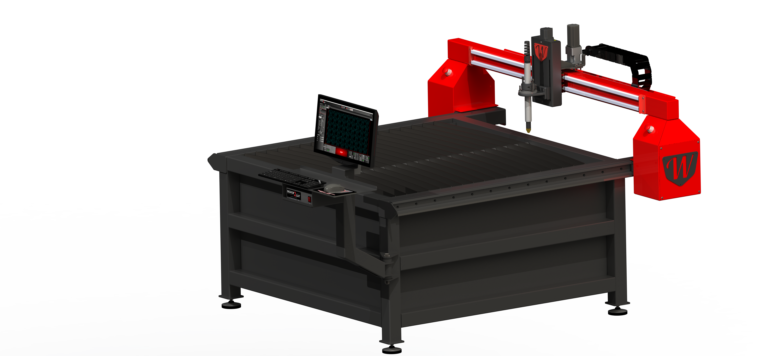

Table Construction

- Available in 3 size configurations to fit your needs and space 4’x4′ 4’x8′ & 5′ 10′

- Integrated computer workstation

- 3″ Deep Water Pan

- Steel fabricated gantry with dual drive system

- Nema 23 454 oz. Stepper Motors

- 3:1 planetary gear boxes with 3 arc-min backlash

- Dual 20mm true linear rail Z axis with 5mm pitch ball screw

- Ohmic sensing

- Billet Westcott Torch holder w/ collision sensors

- Rack and pinion drive system

- 20MM True linear rail with 2 recirculating bearing Blocks per side

- 2 x 20 MM Linear Rails w/ 4 recirculating bearing Blocks on gantry

- Integrated Digital torch height control

- Rapid speeds up to 1000ipm+

- .0004 resolution

- Designed and constructed for light industrial use

- Durable powder coated finish throughout

- Oversized cable carrier system

- Design2Cut™ Control System

- Familiar Windows based operating system

- Remote access machine support available using Team Viewer

- Unlimited tech support and training for the life of the machine

- 1 year warranty on electronics and parts

- Proudly Made in the USA

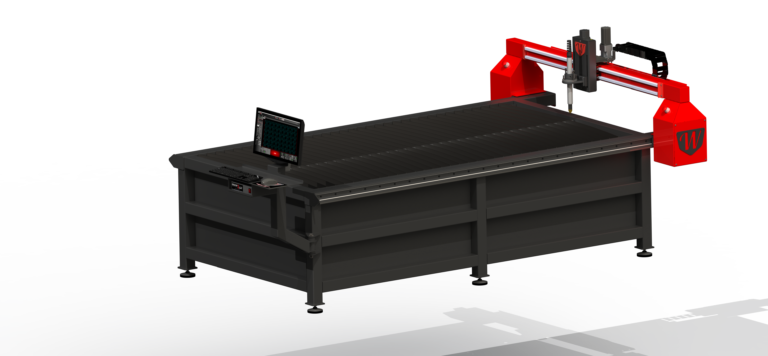

Cutting Systems

The Titan Series X™ Package includes everything you need to start cutting: an advanced electronics drive package, windows based software, controller, and our Design2Cut 3C’s CAD/CAM/CUT productivity suite.

With wifi built in and the ability to have a technician remotely log in to your table to help you troubleshoot issues, brush up on training, or assist you with a specific question. This table has it all.

Pair with any Air Plasma cutter from Thermal Dynamics’ A-Series or Hypertherm’s Powermax Series.

Pricing

Base price for tables before accessories and power supply selection.

Pricing

Base price for tables before accessories and power supply selection.