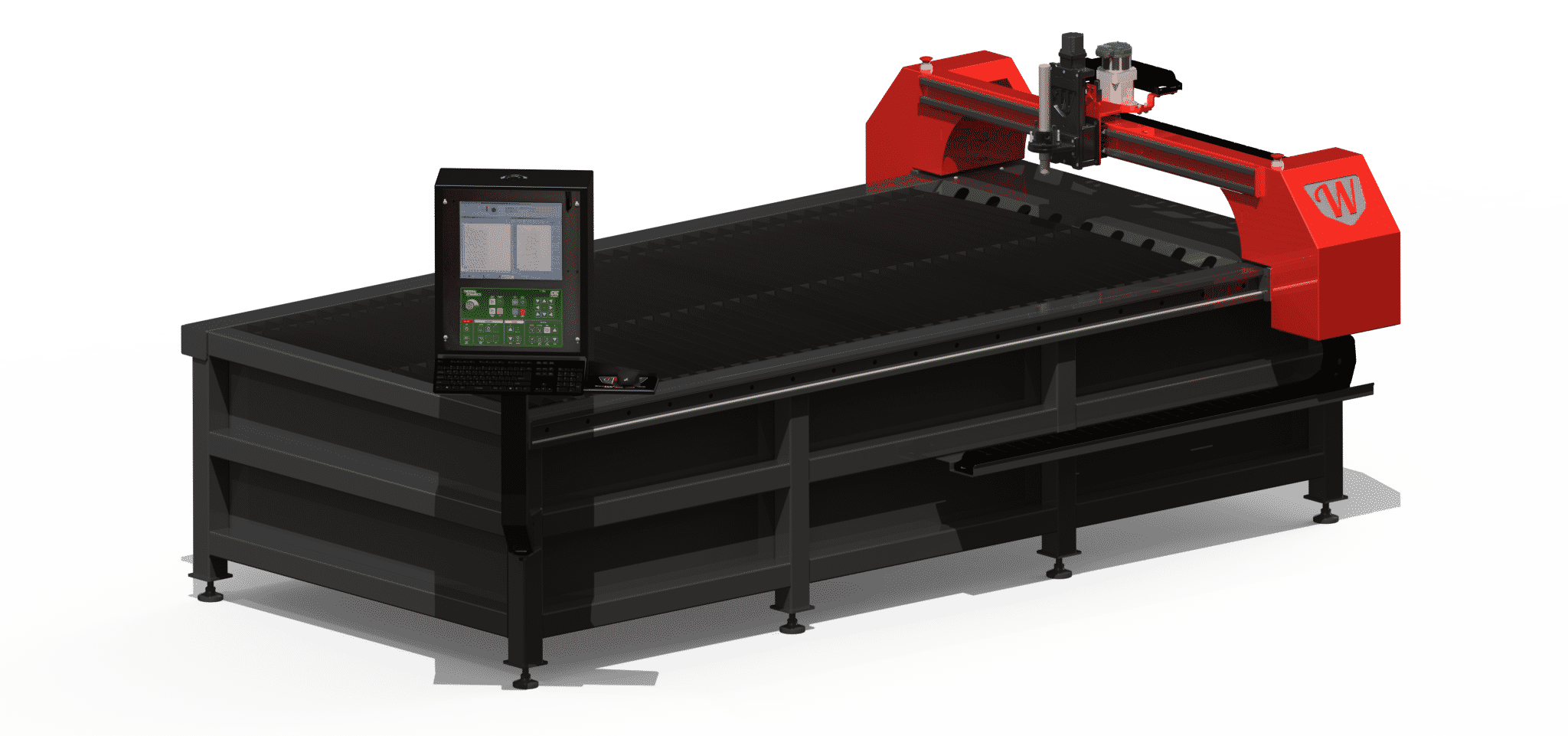

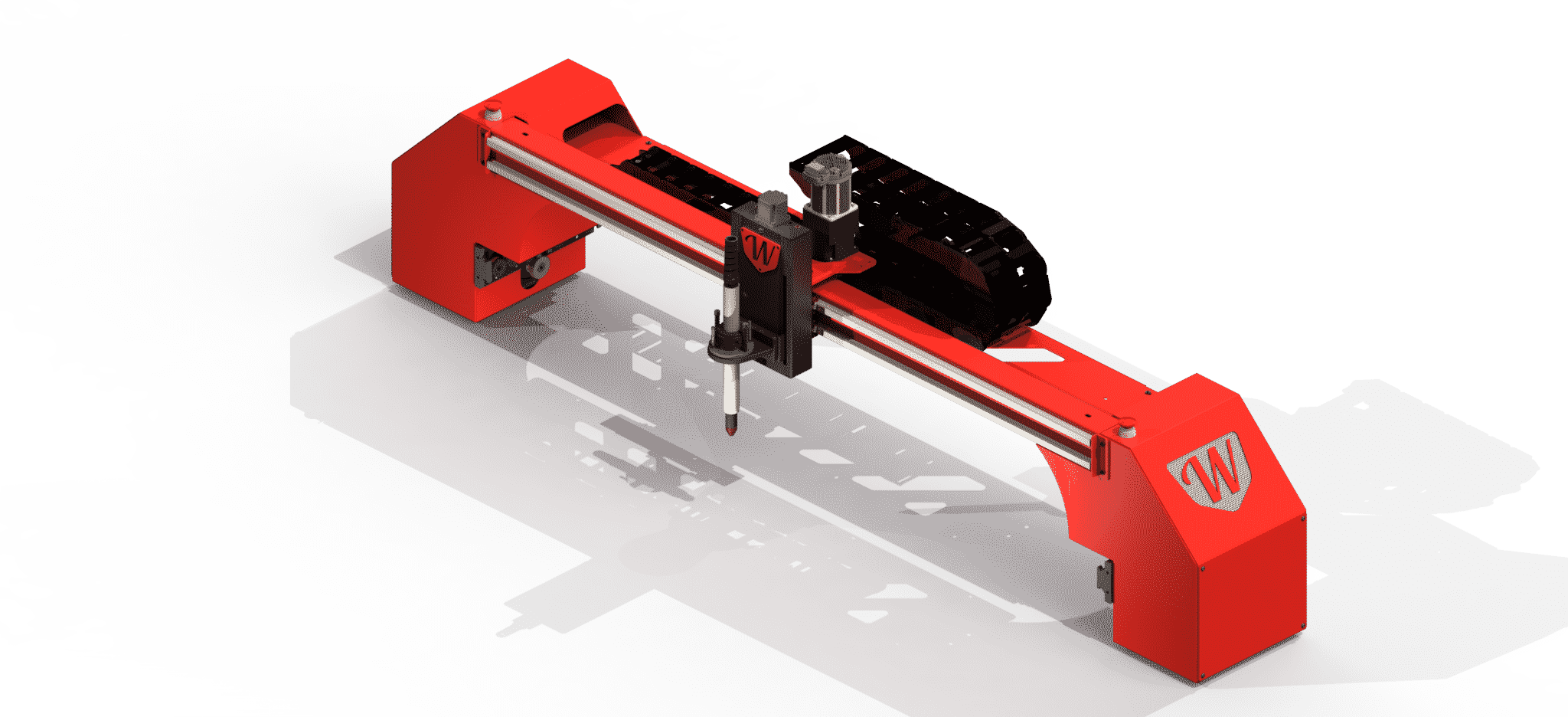

When heavy duty machinery and industrial level precision is needed, our Pro Series HD™ Table powered by iCNC is here to deliver.

- Heavy Duty

- Great for Large Industrial Businesses

- Endless Configurations

Features and Overview

When heavy duty machinery and industrial level precision is needed, The Westcott Plasma Pro Series HD™ Table powered by iCNC is here to deliver.

From the ground up the Pro Series HD™ is designed for heavy use with a fully welded steel construction. The Pro Series HD™ plasma cutting table features a dual chamber adjustable water bed that can be raised and lowered in seconds. No moving parts, no bladder, nothing to ever fail, and best of all no smoke filled shop when cutting.

The water bed system uses only shop air to raise and lower the water level so parts can be quenched and retrieved with ease. The Pro Series HD™ plasma cutting table features an over sized cutting window, so multiple processes can be mounted to suit your needs.

Quick Glance

High Definition Ready

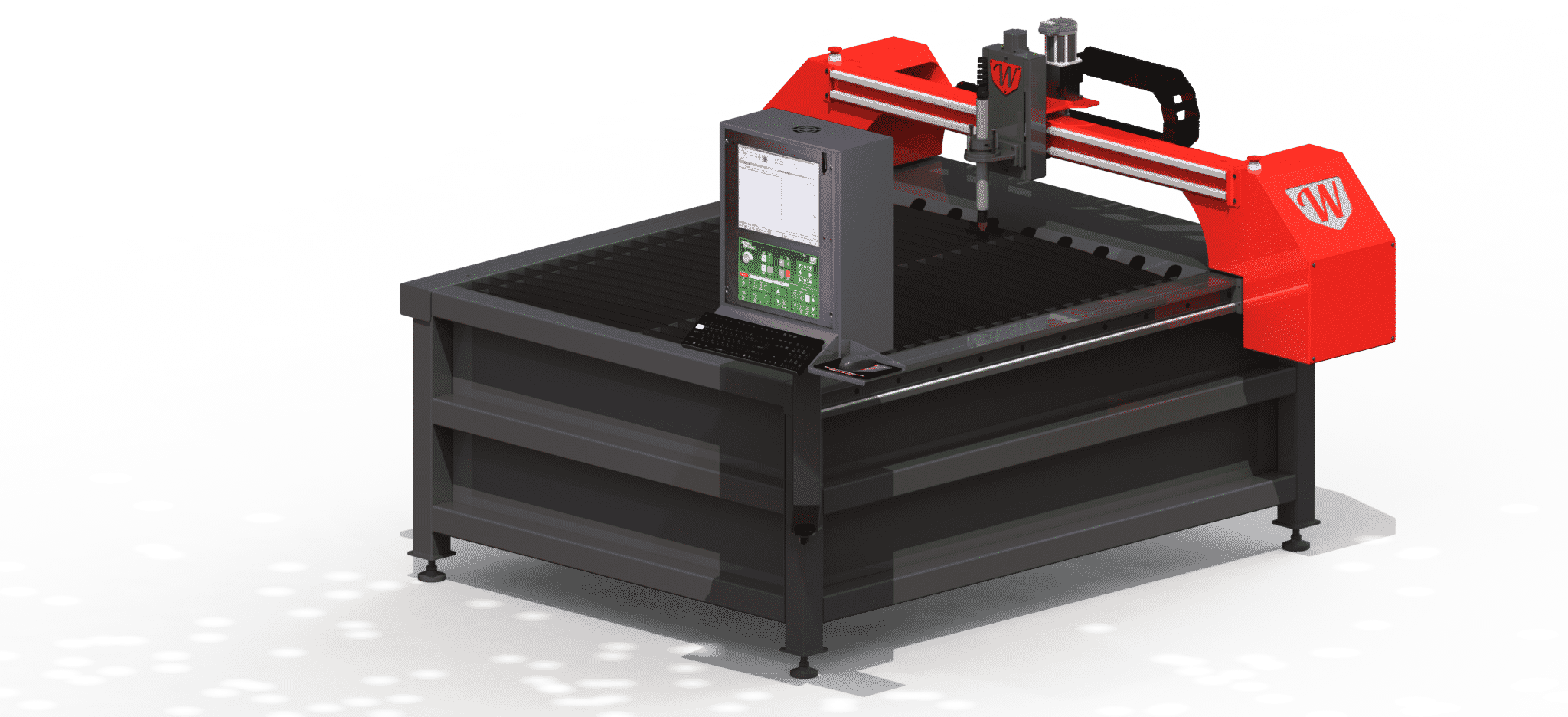

iCNC Controller with Microsoft Windows Environment

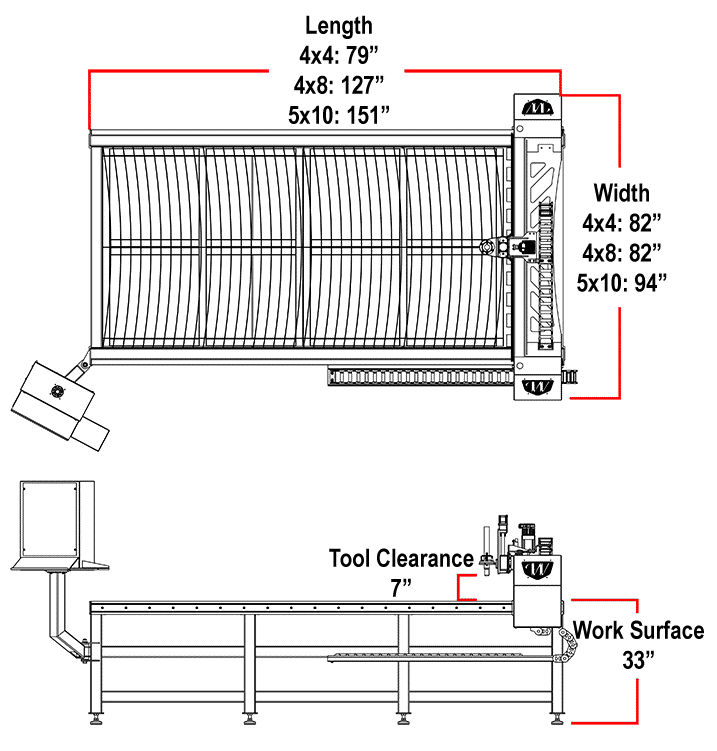

4'x4', 4'x8', 5'x10' Size Configurations

Standard 110 / 220v Single Phase Power *

Teknic ClearPath® Brushless Servo Drive System

Designed for up to 2" plate

*Some higher amperage air plasma power supplies and HD plasma power supplies will require 3ph power.

iCNC INDUSTRIAL CONTROLS

- Macro shapes library - Select from over 42 macro shapes in our shape Library. Then use MicroCAD to create an infinite number of new shapes.

- DXF Converter - Easily converts CAD drawings (DXF files) to cutting programs.

- Change Piercing location - Allows you to change the pierce point to the first point of the element or you can choose any point on the element.

- Kerf Compensation - Gives the ability to change kerf of a profile, allows you to change from kerf left, kerf right and zero kerf.

- Basic Lead-ins - This tool allows you to change the location of the lead in and lead out.

- Change cutting order - Gives the ability to change the cutting order of parts on a nest.

- Rows and Columns - Allows you to create row and column nest (grid array).

- Change cutting direction - Allows you to change the cutting direction from clockwise to counter clockwise.

- MicroCAD - Tool for editing and to create new shapes

- Cost calculator - By supplying the end-users data and real manufacturing costs, the system will calculate the cost to cut your desired nest or parts.

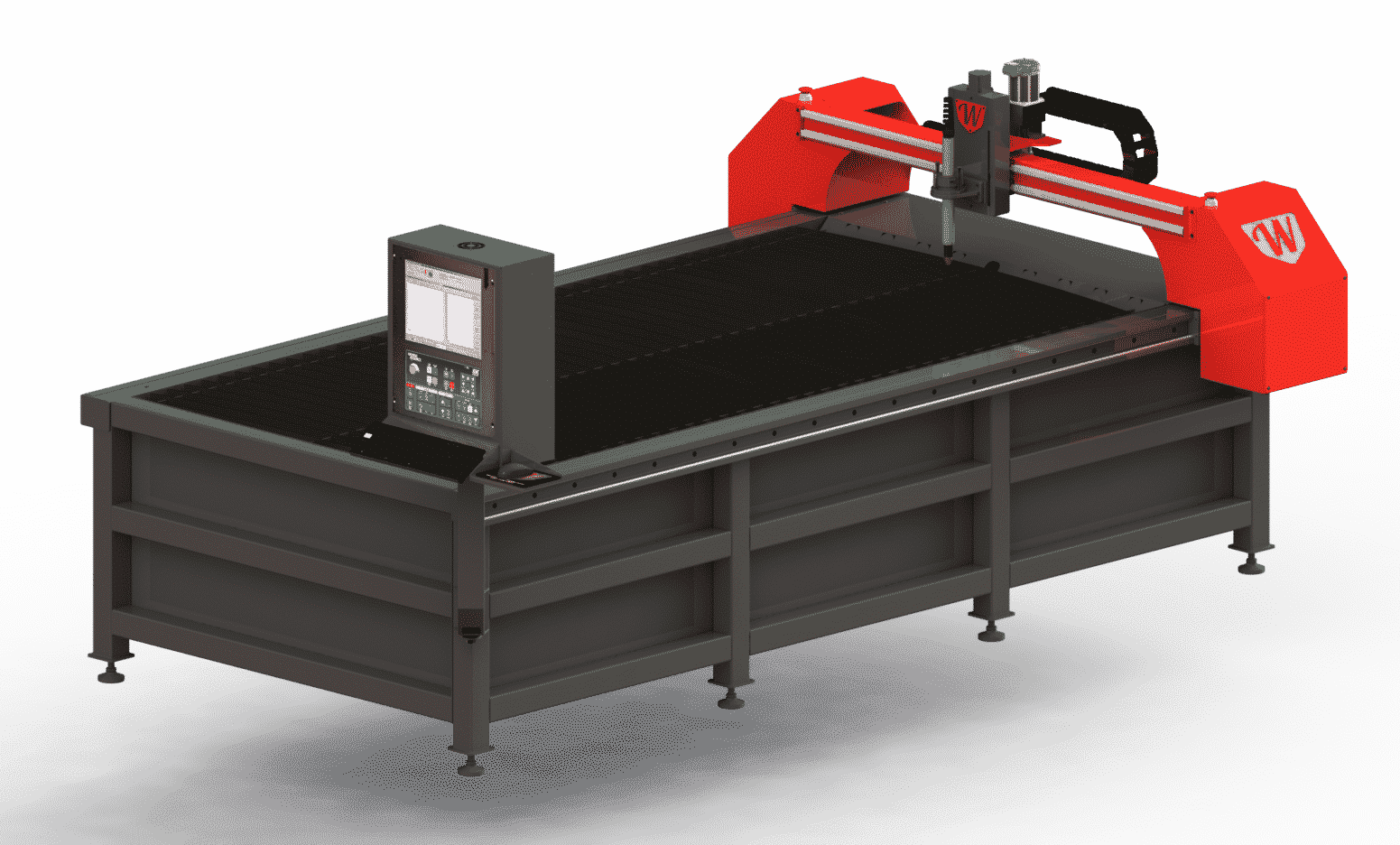

Table Construction

- Dual Chamber adjustable water system which reduces airborne smoke and debris

- Adjustable water height

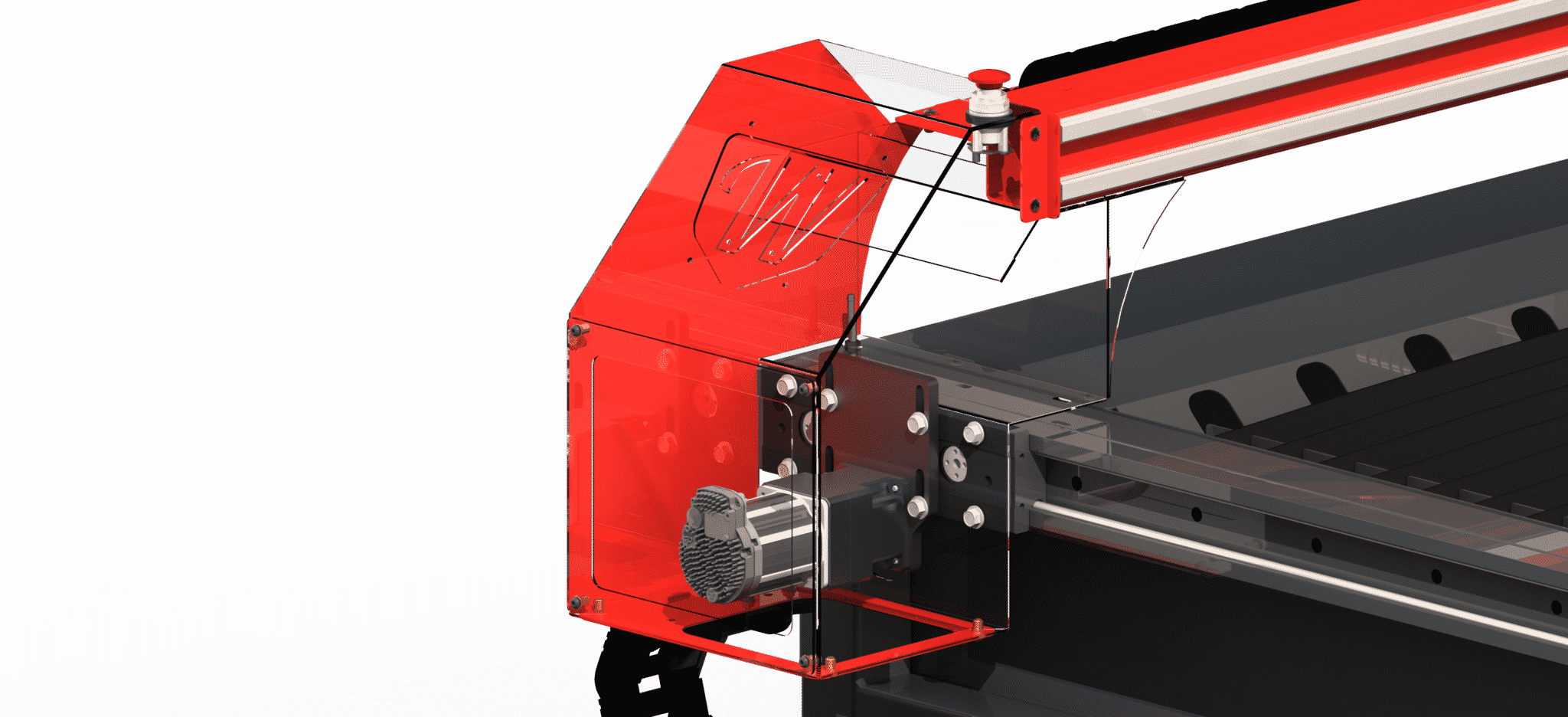

- Steel fabricated gantry with dual drive system

- Nema34 698 oz. Teknic Clearpath Brushless Servo Motors

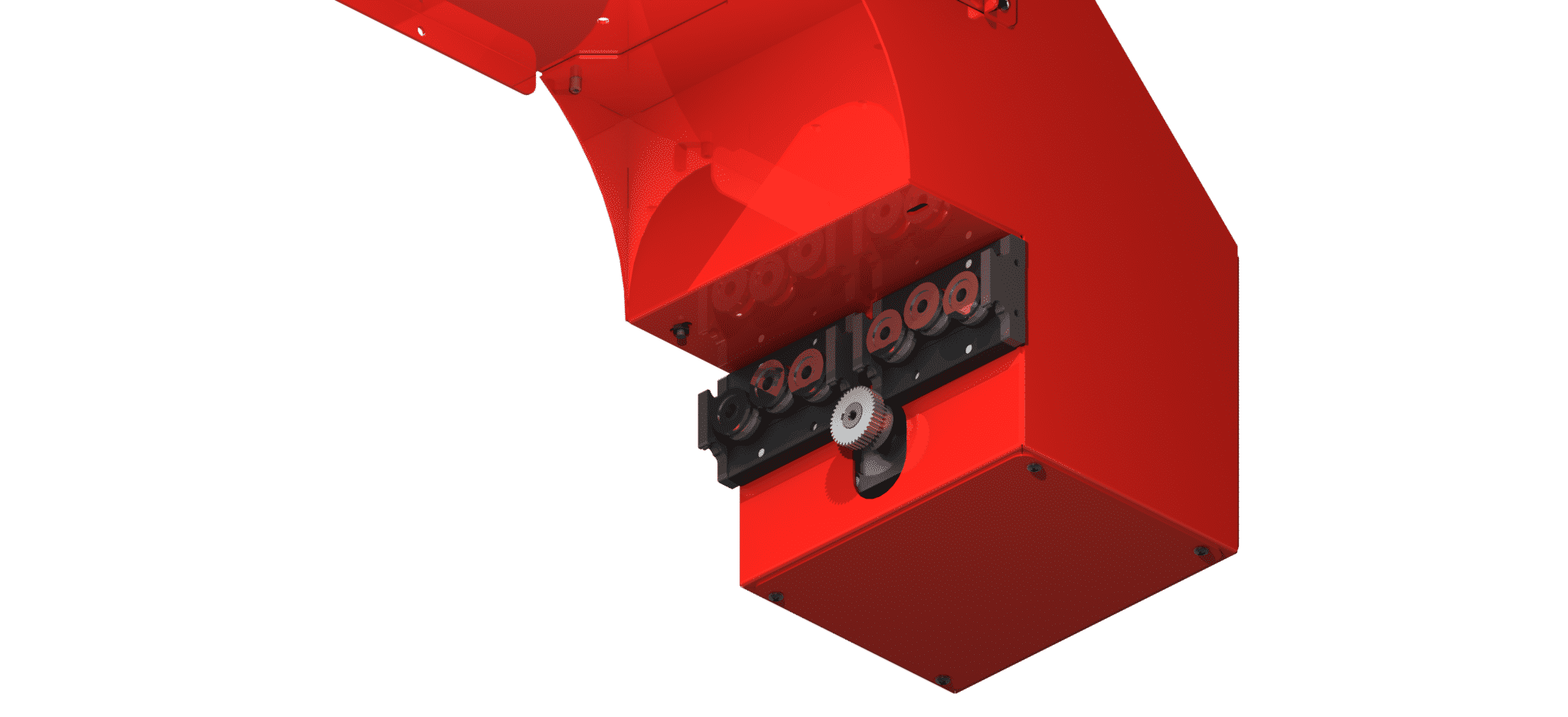

- 10:1 planetary gear boxes with 3 arc-min backlash

- Fabricated sheet metal Z axis with 5mm pitch ball screw

- Ohmic sensing and collision sensors on Billet Westcott Torch holder

- Rack and pinion drive system

- 35MM Precision speed guide rails with 6 roller bearings per side

- 2 x 20 MM Linear Rails w/ 4 recirculating bearing Blocks on gantry

- Digital torch height control

- Rapid speeds up to 1100ipm

- Fastest cycle times in the industry

- .0004 resolution

- Designed and constructed for industrial use

- Durable powder coated finish throughout

- Oversized cable carrier system

- iCNC Industrial Control System

- Familiar Windows based operating system

- Remote access machine support available using Team Viewer

- Unlimited tech support and training for the life of the machine

- Completely tested in house before shipment

- 2 year warranty on electronics and parts

- Proudly Made in the USA

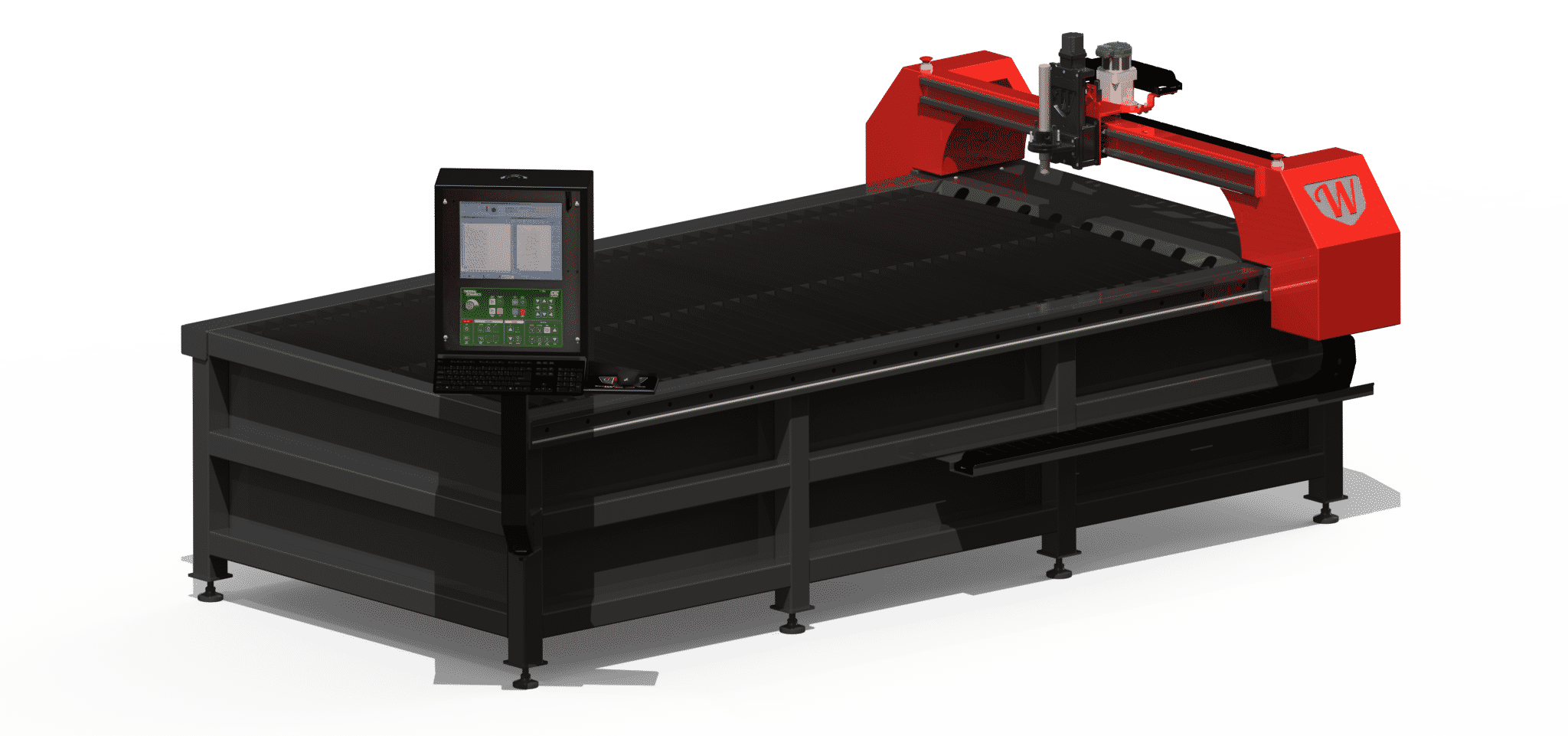

Cutting Systems

The Pro Series HD™ Plasma Cutting tables are High Definition Plasma ready, and can be outfitted with a Thermal Dynamics Ultra-Cut XT system at time of shipping or one can be retrofitted when your shop’s needs expand to require it.

The Ultra-Cut XT systems’ superior cut quality means that parts can go directly from the cutting table to welding, painting or assembly without expensive secondary operations.

Ultra-Cut XT high precision plasma systems cut with:

- Excellent dross-free cuts using oxygen (O2) plasma on mild steel.

- Unmatched cut quality on non-ferrous metals using unique Water Mist Secondary (WMS®) process.

Pricing

Base price for tables before accessories and power supply selection.