Air Plasma

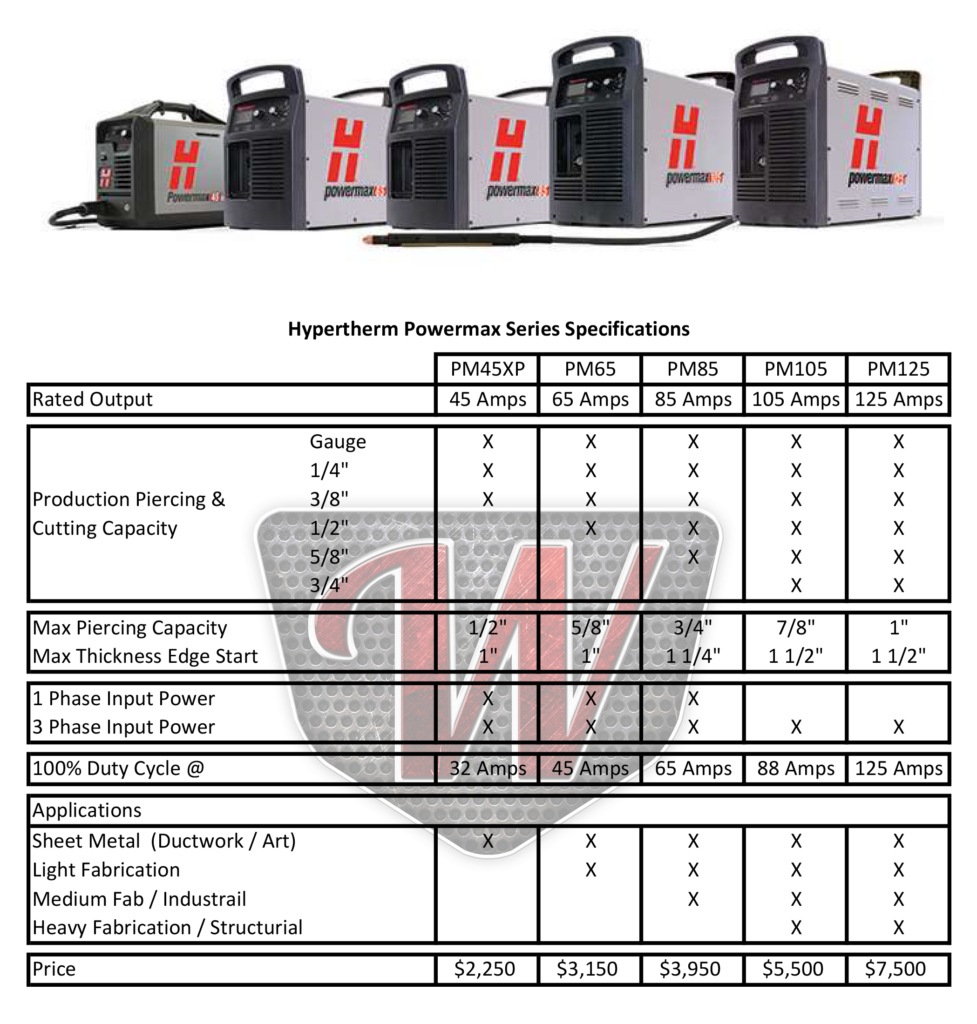

Standard Power Supplies for Pro or Titan Series Tables

Air Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, aluminum, brass and copper, although other conductive metals may be cut as well. Air plasma allows for high speed and precision cuts combined with low cost.

Westcott Plasma is proud to be an OEM integrator for both Thermal Dynamics & Hypertherm. We have put together a quick reference and pricing guide to help making choosing your power supply easier.

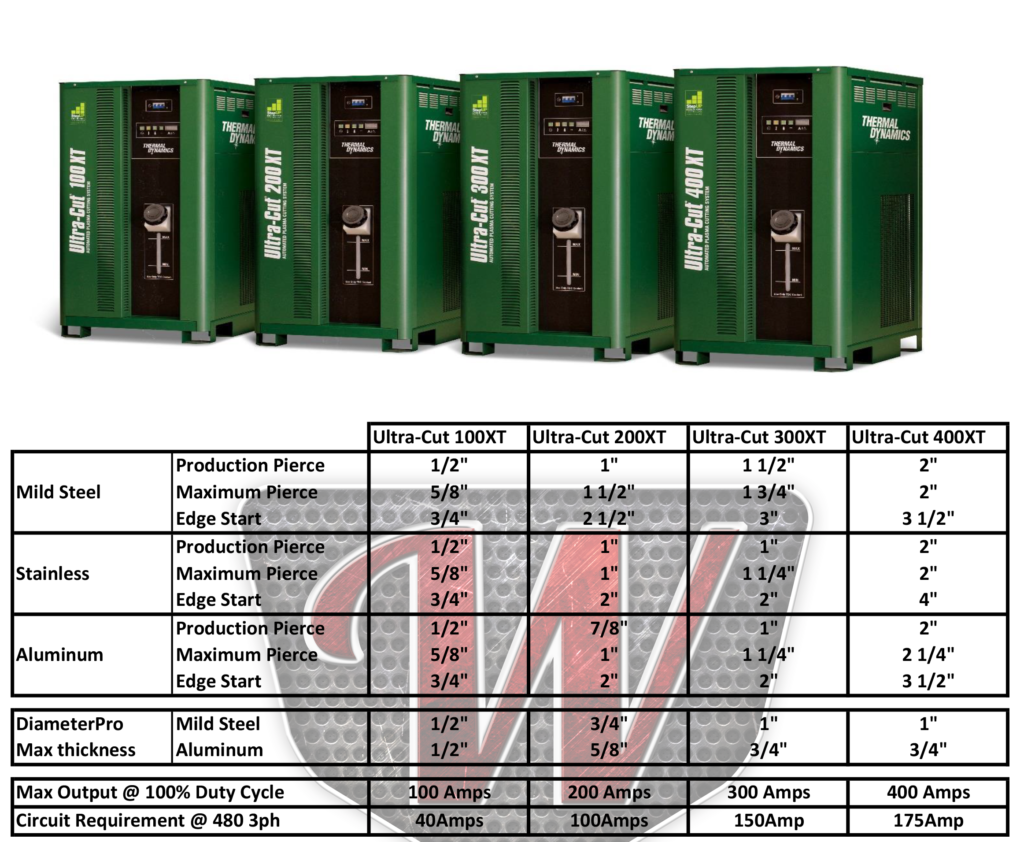

High Definition Plasma

Advanced Cutting Power Supply Systems for Pro Series Only

Ultra-Cut XT High Definition Cutting System

The new Ultra-Cut XT technology provides the next generation of higher productivity, increased flexibility and confidence in high precision plasma cutting. Their performance will meet or beat anyone on mild steel, and they are superior on non-ferrous metals. With the ability to grow with your business, you can expand from one system to the next higher in minutes. The Ultra-Cut XT systems utilize StepUp™ modular power technology, allowing units to be easily upgraded – ensuring you’ll always have the right amount of power today – and tomorrow.

Better Flow Control and Plasma Marking with the DFC-3000 Automatic Gas Control

Good gas flow control enhances cut quality and extends consumables life. Digital flow control with the DFC-3000 — when paired with the iCNC® XT controller — provides a better level of quality control. Together, they instantly set and control gas pressure, leading to faster cycle times and more productive cutting. And for plasma marking with argon, the DFC-3000 and Ultra-Cut XT minimizes the purge cycle between marking and cutting, as well as the changeover time associated with manual controls.

Change seamlessly between cutting and marking to:

- Indicate part numbers

- Drill or hole points

- Weld locations

- Lot numbers

- Bend or cut lines without the need for secondary tooling or offset programming.

Automatically optimizes the holes at the iCNC

The Thermal Dynamics iCNC system has the intelligence built-in to cut optimized quality holes. If automatic optimization is enabled at the iCNC, the system takes advantage of the optimized hole cutting process database and individually reprograms each hole for optimum cut quality. This is the power of an intelligent system,where all individual components including the plasma power source,gas console, torch height control and machine motion are integrated to work seamlessly together.

Accessories

Advanced Cutting Power Supply Systems for Pro Series Only

Auxiliary Process Accessories

Pneumatic Scriber Accessory Kit With Scribe

$1,400

The Westcott pneumatic scribe features an industrial hand tool with hardened steel tip to create single point marks or scribed lines on any metal. This simple and reliable device provides highly accurate marking at high speed. It operates using ordinary compressed air and features an air line oiler for long tool life. The scribe is mounted to our Z tool mounting plate and features a pneumatic slide to raise and lower the tool, it is used in tandem with a plasma cutting head. Allows you to permanently imprint serial numbers or assembly layouts on parts, scribe bending lines for faster braking operations, or etch names and custom designs on to the surface of your work.

- Chicago Pneumatic CP 9361 Industrial Scribe and Engraver

- Billet Aluminum Machined Air Slider 125mm w/ mount

- Pre-assembled filter/regulator/solenoid 4-way valve assembly

- Secondary low pressure regulator

- Pre-assembled filter/ regulator/ lubricator/ solenoid 3-way valve assembly

- All fittings and air line tubing.

Oxy / Fuel Cutting Torch Attachment

$1,995

With the addition of an Oxy / Fuel cutting head the need to choose between oxy fuel and plasma cutting can be eliminated. This provides a great convenience to most shops, allowing them to cut down on overhead, cost, and lost physical space by not having to purchasing different types of equipment. With the ability to cut much heavier plate than plasma systems allow for oxy fuel is a must for many heavy fabrication shops.

- Victor MT 310A Machine Cutting Torch

- Electronically controlled Pressure valves

- Flame Arrestors

- Includes Required hoses (2x Oxygen, 1 x Fuel) + extra 50′ length from table.

- Billet Torch mount for Westcott Z tool plate

- Gauges/Regulators. Tips & Other consumables not included.

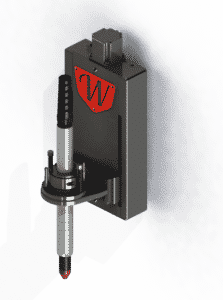

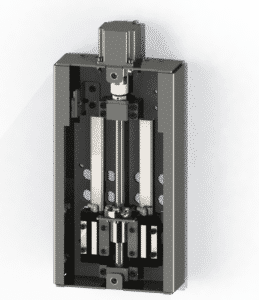

Westcott Z-Axis Torch & Tool Holder

$950

Included on all Westcott Plasma tables, our tried tested and proven Z is available for retrofitting to other systems.

- Billet Aluminum Construction

- Air Plasma / High Definition Plasma Machine Torch Holder

- Hard Anodized Surface

- 5mm Pitch Ball Screw Drive for precision control

- Multiple Process Mounting Plate

- Dual Proximity Sensors flawlessly detects collisions with instant feedback to controller

- 300oz NEMA23 Motor

Westcott CNC Wood Router System

$850

Westcott Router system is available to customers who would like to experiment with using their tables for wood and other carvable materials, please be aware that routing may require 3rd party software. At this time routing is considered an ‘experimental feature’ and Westcott does not offer support for it beyond the hardware installation itself.

- PorterCable 3 1/4 HP Variable Speed Router

- Kent Dust Shoe with magnetic breakaway.

- Billet Aluminum Mounting bracket