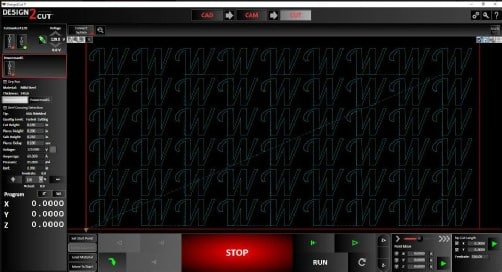

With a downdraft system you are using a plasma table design that tapers down under the table to an exhaust duct. This duct is then connected to a fan to pull the air, dust and smoke down and away from the table. If the table is not designed correctly small parts and pieces that drop down can be difficult to retrieve.

Table position in the shop is critical since you will need to place it close to an exterior wall or use a vertical stack for ventilation. The ducting can be a trip hazard and obstacle around the table. You’re going to need a large and powerful fan to pull all of that smoke and dust down. Picture a 4×8 table, you have 32 square feet of space you need to pull the air down evenly across this entire space and exceed the tendency of the smoke to rise from heat.

The design of the downdraft system is critical so that it effectively pulls the smoke and dust down over the entire area and not just the center. This is an area where I often see downdraft tables fail. They may pull the smoke and dust down when cutting over the center of the table but when cutting anywhere else its not effective. Also you need to usually cover areas not in use to increase the vacuum affect. If you have a 4×8 table and your cutting a 4×4 piece of steel, most down draft systems air will take the path of least resistance and be pulled through the area where there is no steel and allow the dust and smoke to escape where you’re cutting. The Westcott Plasma Pro Series table is designed to get around this affect.

Call for more info: 480-220-2177

All of the air that you’re pulling through this system has to come from somewhere right? That air is your heated shop air in the winter and your cooled shop air in the summer. So you’re going to be pulling hundreds of cubic feet a minute of air out of the shop. This can dramatically increase your utility bills. Venting direct to the outside is common but it can make a mess of the area where it vents and you will have the smell of smoke being pushed outside. Units to clean the air and reuse it can cost thousands of dollars. And you will have more noise and electricity use due to the operation of the fan.

Lastly with a downdraft system your metal will be hotter and stay hotter longer. Warping of thin material is much more common and will give your THC a work out keeping up with the warping material. This warped material can also be a pain to deal with when finishing the part. You can often just look at plasma cut parts and determine visually if they were cut on a water table or a downdraft. There will be a blue haze around the downdraft cut parts edges from the extra heat the metal experiences.

Advantages

- Usually less expensive to maintain once installed

- Cleaner with less secondary mess

- Drop out parts can be easier to find depending on design

- Captures about 70 to 80 percent of dust and smoke

Disadvantages

- Requires more equipment such as a fan and uses more energy

- Pulls shop air outside thus your heated or cooled shop looses its air and you could have much higher utility bills

- Warping of parts is more common due to heat

- Larger heat affected zone on parts

- Usually requires covering unused portion of table to be effective

- Parts stay hot longer and burns from handling parts are more common

- Can have zones or areas where its less effective than other areas on the table

In conclusion, even though there are a lot of disadvantages to the downdraft design, some people prefer to have less of a mess. Others prefer a water table design, which is one of the most common types of cnc plasma tables. To learn more about the difference between the two, check out our Water Table vs. Downdraft Article.