The plasma cutting process, as used in the cutting of electrically conductive metals, utilizes this electrically conductive gas to transfer energy from an electrical power source through a plasma cutting torch to the material being cut.

The basic plasma arc cutting system consists of a power supply, an arc starting circuit and a torch. These system components provide the electrical energy, ionization capability and process control that is necessary to produce high quality, highly productive cuts on a variety of different materials.

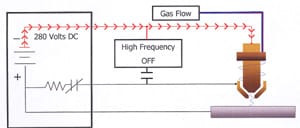

The power supply is a constant current DC power source. The open circuit voltage is typically in the range of 240 to 400 VDC. The output current (amperage) of the power supply determines the speed and cut thickness capability of the system. The main function of the power supply is to provide the correct energy to maintain the plasma arc after ionization.

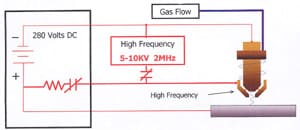

The arc starting circuit can be Blowback design which is used on the Hypertherm Powermax Series or a high frequency generator circuit that produces an AC voltage of 5,000 to 10,000 volts at approximately 2 megahertz. This voltage is used to create a high intensity arc inside the torch to ionize the gas, thereby producing the plasma.

The Torch serves as the holder for the consumable nozzle and electrode, and provides cooling (either gas or water) to these parts. The nozzle and electrode constrict and maintain the plasma jet.

The Sequence of Operating a Plasma Cutter

The power source and arc starter circuit are connected to the torch via interconnecting leads and cables. These leads and cables supply the proper gas flow, electrical current flow and high frequency to the torch to start and maintain the process.

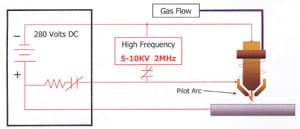

STEP 1: A start input signal is sent to the power supply. This simultaneously activates the open circuit voltage and the gas flow to the torch (see Figure 2). Open circuit voltage can be measured from the electrode (-) to the nozzle (+). Notice that the nozzle is connected to positive in the power supply through a resistor and a relay (pilot arc relay), while the metal to be cut (work piece) is connected directly to positive. Gas flows through the nozzle and exits out the orifice. There is no arc at this time as there is no current path for the DC voltage.

STEP 2: After the gas flow stabilizes, the high frequency circuit is activated. The high frequency breaks down between the electrode and nozzle inside the torch in such a way that the gas must pass through this arc before exiting the nozzle. Energy transferred from the high frequency arc to the gas causes the gas to become ionized, therefore electrically conductive. This electrically conductive gas creates a current path between the electrode and the nozzle, and a resulting plasma arc is formed. The flow of the gas forces this arc through the nozzle orifice, creating a pilot arc.

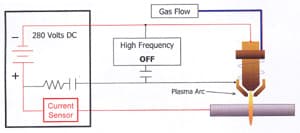

STEP 3: Assuming that the nozzle is within close proximity to the work piece, the pilot arc will attach to the work piece, as the current path to positive (at the power supply) is not restricted by a resistance as the positive nozzle connection is. Current flow to the work piece is sensed electronically at the power supply. As this current flow is sensed, the high frequency is disabled and the pilot arc relay is opened. Gas ionization is maintained with energy from the main DC arc.

STEP 4: The temperature of the plasma arc melts the metal, pierces through the work piece and the high velocity gas flow removes the molten material from the bottom of the cut kerf. At this time, torch motion is initiated and the cutting process begins.

Variations of the Plasma Cutting Process

Conventional Plasma Cutting

This process generally uses a single gas (usually air or nitrogen) that both cools and produces the plasma. Most of these systems are rated at under 100 Amps, for cutting materials under 5/8″ thick. Primarily used in hand held applications.

Dual Gas Plasma Cutting

The Dual Gas (Oxy-Fuel) Plasma Cut process utilizes two gases; one for the plasma and one as a shield gas. The shield gas is used to shield the cut area from atmosphere, producing a cleaner cut edge. This is probably the most popular variation, as many different gas combinations can be used to produce the best possible cut quality on a given material.

Water Shield Plasma Cutting

Water Shield Plasma Cutting is a variation of the dual gas process where water is substituted for the shield gas. It produces improved nozzle and work piece cooling along with better cut quality on stainless steel. This process is for mechanized applications only.

Water Injection Plasma Cutting

Water Injecting Plasma Cutting uses a single gas for plasma and utilizes water either radially or swirl injected directly into the arc to greatly improve arc constriction, therefore arc density and temperatures increase. This process is used from 260 to 750 amps for high quality cutting of many materials and thicknesses. This process is for mechanized applications only.

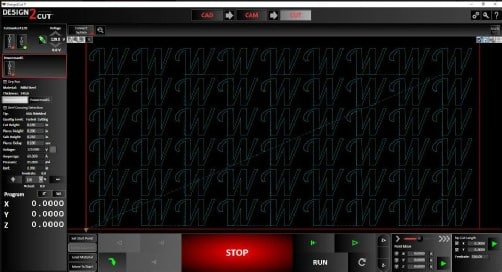

Precision Plasma Cutting

Precision Plasma Cutting produces superior cut quality on thinner materials, (less than 1/2″) at slower speeds. This improved quality is a result of using the latest technology to super constrict the arc, dramatically increasing energy density. The slower speeds are required to allow the motion device to contour more accurately. This process is for mechanized applications only.